Level Measurement is essentially measuring the level of fluid or solids in a tank (above or below ground) or silo (mostly for solids).

Discontinuous or Point Level Measurement

This measurement can be discontinuous like sensing when the level is at some value(point level) in the tank or silo. This is done by Level Switches for point level detection. Generally, the switches are designed to generate an open or closed contact when a point Level is reached which can be used for indication & alarming (locally or remotely).

Continuous Level Measurement

More widely used are continuous level measurements which can also provide variable point level detection or alarms.

Continuous Level measurement examples could Large Elevated Storage Reservoirs for continuous water supply to a township or community or industry. Here water needs to be continuously measured controlling the optimum head pressure in the tank for proper water discharge pressure & flow to the consumers.

Continuous Level Measurements are also important for storage tanks & silos in industry & power plants to know the inventory & control the same.

Such measurements are also important for Process/Mixing Tanks/Reactors to satisfy process operational requirements, which determine the product quality & reliability.

To ensure the safety and profitability of the process, accurate level measurement is mandatory. In every process industry, a level transmitter is an important instrument that can be used to prevent overflow or any undesirable condition in the reactor and other vessels.

Based on the process media and process condition, different types of level transmitters are used. Level transmitters are used widely in Water Distribution & Storage, in multiple industrial sectors such as the petrochemical industry, chemical making & refinery units, etc.

RLT Instrumentation manufactures online digital Level Transmitters using time-proven & latest technologies.

In this post, we will give an overview of different Continuous Level Measurement Technologies

& dwell more on the relevant technologies of interest today & in the future.

Different types of level transmitter

There are so many different types of level transmitters available for level measurement in the market, each with its own advantages and limitations. Based on the application area and process media, level transmitters are suggested.

Ultrasonic level transmitter working principle

Ultrasonic level transmitter working principle is based on the principle of time of flight. It is a non-contact type level transmitter that is installed on the top of the tank above the process media in the tank. Audible Sound Frequency is up to 20kHz. Above 20kHz is Ultrasonic sound which is used to measure the level. Ultrasonic Level detection operates by the resonance ring time of an ultrasound signal transmitted from and received by the same sensor mounted on the top of the tank.

It’s a simple matter of the digital electronics to calculate the level of the process fluid or solid know the speed of the signal & the time of flight . This happens on a continuous basis. The ULT can provide a local display and/or give an output conforming to standard instrumentation signals(like 4 to 20mA, etc).

An important USP of the RLT ULT is it uses an IR Temperature Detector against conventional RTD temperature elements.

The User benefits are

- Measures the actual process temperature at the surface of the process media providing more accurate & faster resposne.

- It’s more rugged as compared to RLT element .Once this fails ,the instrument cannot be repaired & has to be replaced.

- Ultrasonic LT can measure up to 30 M in liquids.

Working principle of radar level transmitter

This is again a non-contact type of LT using Radio Waves in the Microwave Range.

The Microwave signal reflects from the top of the process surface & the same time of flight principle applies here too.

The amount of microwave reflected depends upon the dielectric constant of the process media.

The advantage of Microwave Technology is these signals are relatively un effected by changes in pressure & temperature in the process & very accurate.

Hence Radar LT is used for larger Vessels & measurement heights up to 100 meters or so.

For certain specific applications, say for instance Measurement of Solid Powders, the GuidedWave Radar has a better performance. Of course, here the Radar signals travel along guide wires while the same principle of time of flight applies here too.

Working principle of hydrostatic level transmitter

The hydrostatic level transmitter works based on pressure measurement. The working principle of hydrostatic level transmitter pressure at the bottom of a vertical vessel containing materials is directly proportional to the height of the vessel. This principle allows us to measure the level (height) of liquid in a vessel. Hydrostatic level transmitters are loop-powered and cost-effective transmitters that measure the liquid level accurately. As the hydrostatic level transmitter is in compact size it fits perfectly with smaller size pipes. Due to its high reliability and robustness, it is highly popular among industries.

Same is widely used for Borewells & Tubewells. This is mandatory now as per Ground Water Authority Rules.

There are some other technologies used for very special applications. These are Electromechanical Type (used in volatile organic storage tanks ), Capacitance Level for Food Processing applications, Magneto-restrictive LT’s for again volatile fluids, etc.

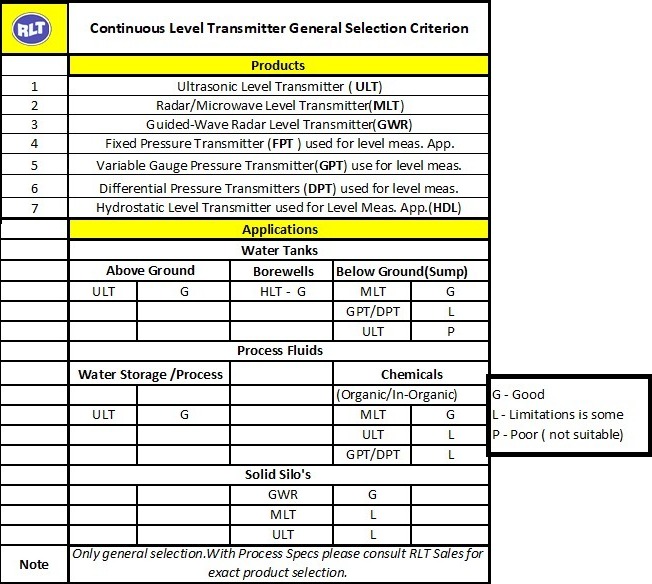

General Selection Criterion of Level Transmitters for common applications

Level Transmitter Application

1.Level measurement in softdrink industry in India

During the manufacturing process, some raw materials should be maintained at a certain level for smooth maintenance of the process and quality of the product. For example, In the soft drink industry, to attain their standard product quality, the calculated amount of ingredients in processing should be followed. Thus a level transmitter is used in the storage tank for proper monitoring of ingredient levels in the soft drink manufacturing process.

2.Inventory Management

In inventory management to keep track of inventory in terms of volume or weight level transmitters are used. In custody transfer, accurate measurement of materials is necessary as minute errors would cost more in terms of volume. Based on the type of transfer either commercial or legal, the device would vary.

3.Cement silo level measurement

Accurate level measurement increases efficiency. For example, In Cement Industry, level transmitters are especially used in cement silos to monitor the level of process materials used for the manufacturing of cement and other building materials. Cement silos are the warehouses where cement and other concrete materials are stored. Thus it improves the process efficiency.

Conclusions

These are all about the working principle of the level transmitter. RLT Instrumentation, with its 25 years of technical expertise in the field of instrumentation, manufactures highly accurate different types of level transmitters in an advanced manufacturing facility and supplies all over India.

Hope you find this blog useful and informative. Let me know what you think in the comment section below

“Get in touch with us today to learn more about our products and services”. Let’s help you prevent pollution & add value to global sustainability!.

FAQ

What is level measurement ?

Level measurement is all about determining the position of a surface inside a reactor, or vessel containing materials.

What is called a Level Transmitter ?

A Level transmitter is an instrument to measure an accurate liquid / solid level in the process container. It involves interaction between the product or material inside a container and a sensing system, device, or element.

What are the Different types of level transmitter ?

- Capacitance type level transmitter

- Hydrostatic level transmitter

- Magnetostrictive level transmitter

- Radar level transmitter

- Electromechanical level transmitter

- Ultrasonic level transmitter

Working principle of capacitance type level transmitter ?

A capacitance level transmitter is used for a wide variety of liquids, solids, semisolids, and slurries. The working principle of capacitance type level transmitter is based on the change in electrical capacitance of a capacitor formed by the sensor, the dielectric material, and the vessel wall. It can sense material with a dielectric constant from 1.1(low) up to 88(high). The vessel wall and sensor both act as electrodes and the material being measured acts as dielectric capacitors. Capacitance directly depends on the liquid level.

Working principle of hydrostatic level transmitter

The hydrostatic level transmitter works based on pressure measurement. The working principle of hydrostatic level transmitter pressure at the bottom of a vertical vessel containing materials is directly proportional to the height of the vessel. This principle allows us to measure the level (height) of liquid in a vessel. Hydrostatic level transmitters are loop-powered and cost-effective transmitters that measure the liquid level accurately. As the hydrostatic level transmitter is in compact size it fits perfectly with smaller size pipes. Due to its high reliability and robustness, it is highly popular among industries.

Working principle of magnetostrictive level transmitter

It has a setup consisting of an auxiliary rod surrounded by a float, a magnet inside the float imparts a magnetic field over the rod. The auxiliary rod discharge electric current at regular time intervals that pass through the auxiliary rod creates a stationary static magnetic field around the float in return it creates torsional stress on the metal rod now that stress move as a stress wave in both directions from the location of the magnet at the free end there’s a dampener that dampens out that torsional vibration so it doesn’t reflect back but on the other end no such dampener over thus it travels over the rod and torsional vibration is detected by an electronic circuit. Thus for highly accurate measurement, Magnetostrictive Level Transmitters are used in fuel depots, chemical injection tanks, wet scrubbers, and storage tanks.

Working principle of radar level transmitter

Radar level transmitters use radio wave emission for detecting the level of liquid/solids in the vessel. These transmitters are fitted on the top of reactor vessels, emit radio signals that hit the process material and reflect back to the sensor. Using the time taken by the wave to emit and reflect the level of material calculated. Radar-level transmitters can be advisable for extreme process conditions. It is also a non-contact level transmitter like ultrasonics, with a fundamental difference in the type of wave used.

Working principle of electromechanical level transmitter

In this electromechanical level transmitter, a sensor weight is lowered into the vessel containing the process material. When the sensor weight hits the material, the tensile force of the weight is reduced which triggers a change in rotation of the motor, which brings the sensor back to the upper stop position. Thus level is measured electronically while the weight is lowered. The obtained measurements are processed by microprocessors then converted into a volumetric output signal. It can be used in undesirable or extreme conditions as it is not affected by sound waves, dust, static electricity, humidity, dielectric etc.

Ultrasonic level transmitter working principle

Ultrasonic level transmitter working principle is based on the principle of time of flight. It is a non-contact type level transmitter that does not need to touch the material to measure. Sonic is the sound frequency of 20kHz, which is human hearable. Above 20kHz is Ultrasonic sound which is used to measure the level. The sensor fitted on the top of the vessel creates a sound wave that hits the process material and reflects back to the sensor. Thus the time taken to hit and reflect is used to calculate the level of the material. It can be used to measure acid and also base.